- Home

- >

- Products

- >

- Tungsten Carbide Strips

- >

- Wear Resistance Hard Metal Sticks For Wearing Part Use

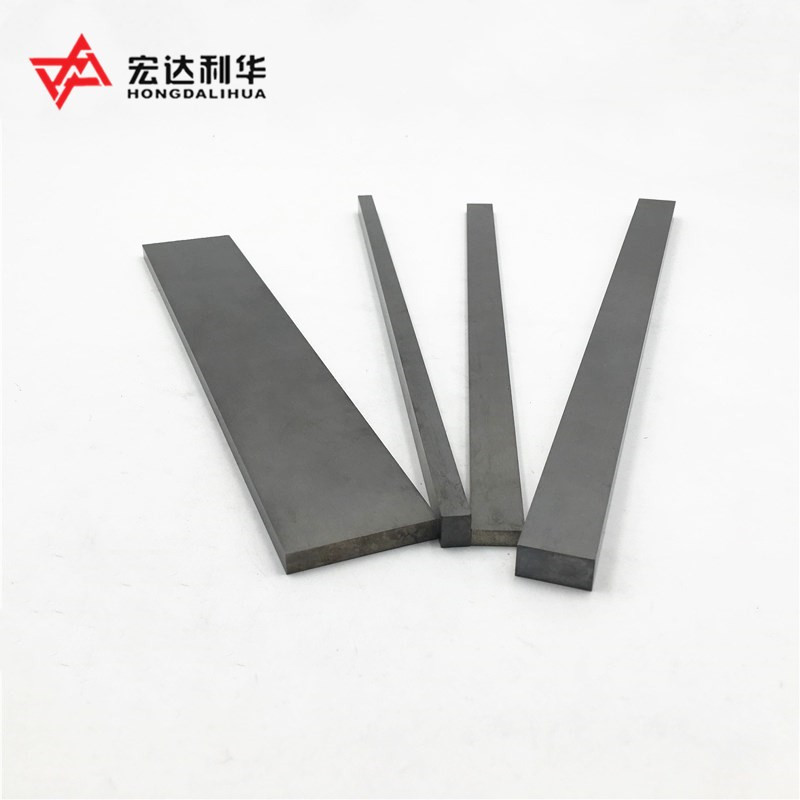

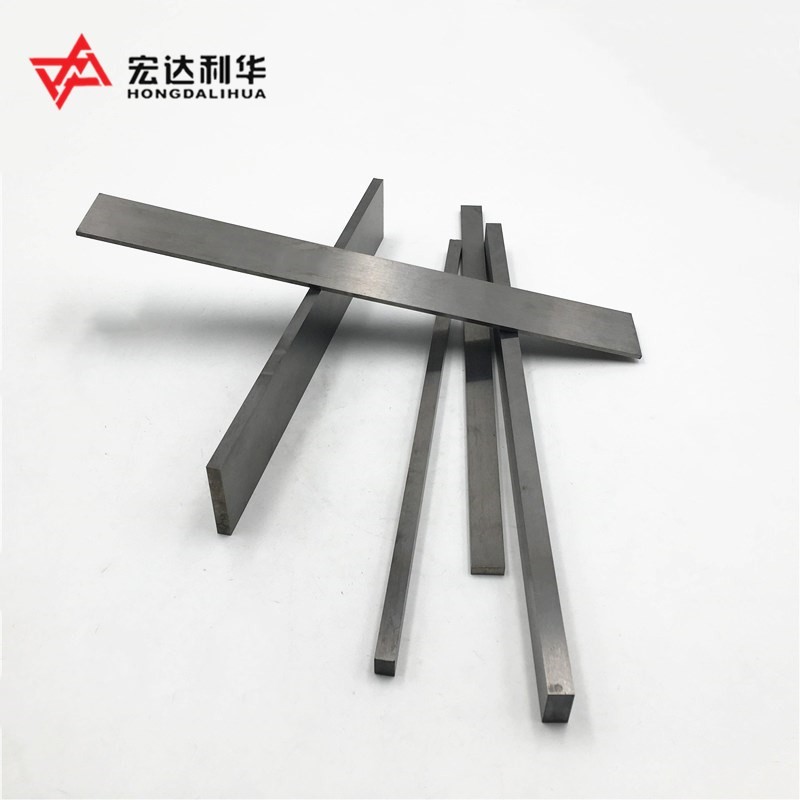

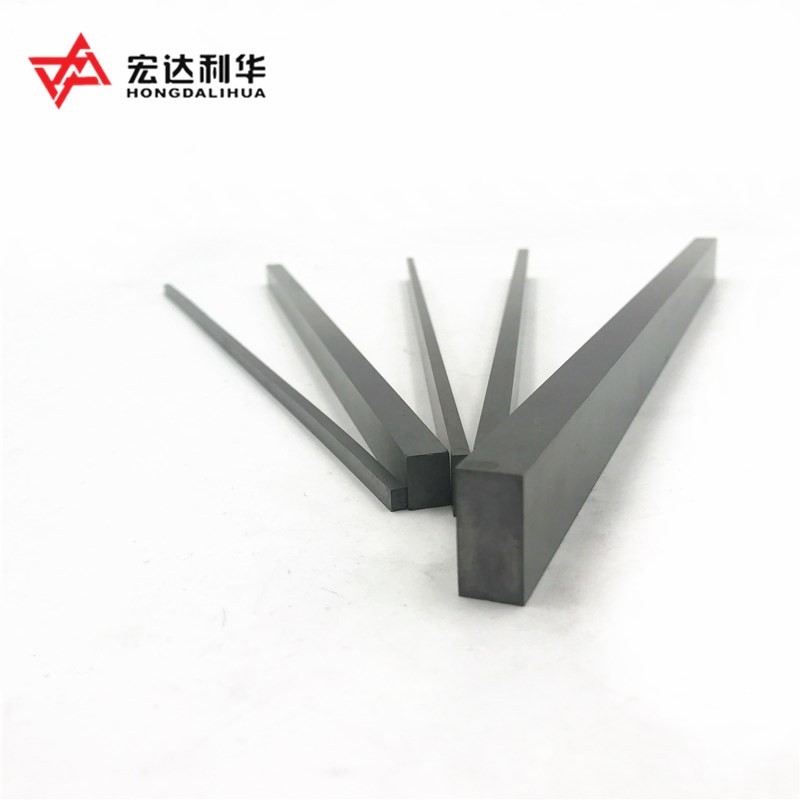

Wear Resistance Hard Metal Sticks For Wearing Part Use

Brand :Lihua

Product origin :Zhuzhou, China

Delivery time :7-15 Working Days

Supply capacity :15 Ton per Month

Wear Resistance Hard Metal Sticks For Wearing Part Use

Applications:

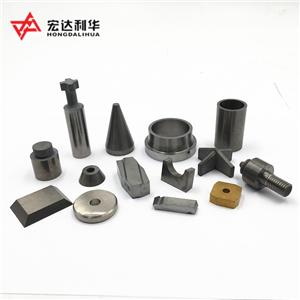

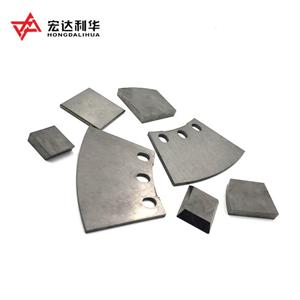

Tungsten Carbide Strips for Machine Tools. Usually used for general wood cutters / hard wood cutters, plastic and tobacco cutting . and meet the ISO9001:2008 quanlity standard. We can make the shipment in the shortest delivery time wtih the compeititve price than any other factory. The application of tungsten carbide strip for woodworking cast iron cutting tool. It can be used in many field such as woodworking, machining of refractory alloys, stainless steel, high manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar, etc

Advantages

1. Superior heat stability

2. Anti-deformation in high temperature

3. Fine thermal shock resistance

4. High thermal conductivity

5. Excellent Oxidation control ability

6. Strong anti-corrosion in high temperature

7. Good corrosion resistance from Chemical

8. High-wearing feature

9. Long usage lifetime

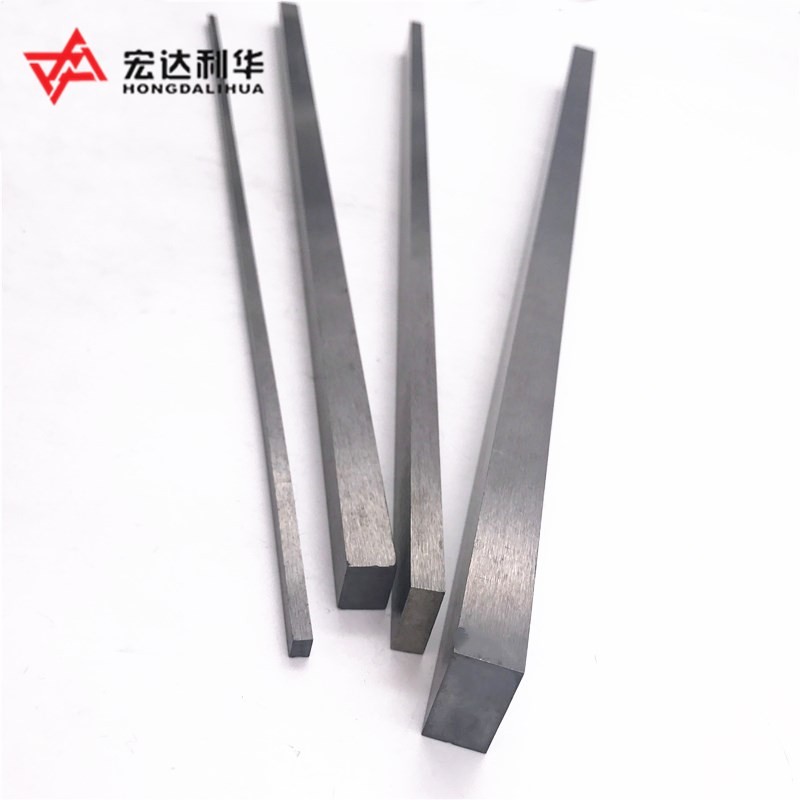

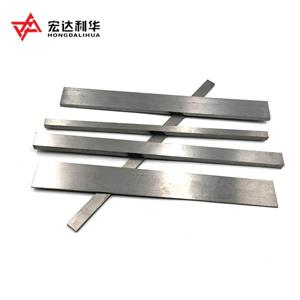

Physical and mechanical properties of grades for cemented carbide square yg8 flat bar/strips tungsten k10&k20 carbide bar/strips for wood&metal cutting. Size of cemented carbide square yg8 flat bar/strips

Tungsten k10&k20 carbide bar/strips for wood&metal cutting

Grade, Properties and Applications of Carbide for Strip

Grade | Density | T.R.S (MPa) | Hardness (HRA) | Performance & application recommended | ISO |

YG6 | 14.8 | ≥2150 | ≥90.0 | High wear resistance, used for hard wood, used for processing original wood, aluminum section bar, brass rod and cast iron. | K20 |

YG6A | 14.9 | ≥1860 | ≥92.0 | Better wear resistance than YG6, used for processing hard wood, original wood , aluminum section bar, brass rod and cast iron. | K10 |

YG8 | 14.8 | ≥2320 | ≥89.5 | Wear and percussion resistance, used for processing hard wood, soft wood, ferrous and non-ferrous. | K30 |

YS2T | 14.8 | ≥2350 | ≥92.0 | Fine grain carbide, high wear resistance , high bending strength, high resistance to bonding, high thermal. Machining of refractory alloys, stainless steel and high manganness steel, etc. | M10 |

YS25 | 13.8 | ≥2200 | ≥91.0 | Carbide grade with high hardness and good wear-resistance, suitable for rough turning, milling and planing of carbide steel, cast steel, high intensity steel and steel alloy. | P25 |

YL10.2 | 14.5 | ≥2150 | ≥92.2 | Wear resistance and strength comparatively higher, suitable for processing cast iron, non-ferrous and non-metal , materials. | \ |

Dimensions of Tungsten Carbide Strips | |||

Unit (mm) | |||

Type (T×W×L) | Tolerance of T | Tolerance of W | Tolerance of L |

1.0 ×(2~5) × L | 0.2~0.6 | 0.2~0.6 | L<100 (0~+1.0) 320>L≥100 (0~+2.0) L=320 (0~+5.0) |

1.5×(2~10) × L | |||

2.0 ×(3.5~15) × L | |||

2.5 ×(3.5~20) × L | |||

3.0 ×(3.5~20) × L | |||

3.5 ×(3.5~25) × L | |||

4.0 ×(4.0~30) × L | |||

5.0 ×(4.0~40) × L | |||

6.0 ×(5.0~40) × L | |||

(7~20) ×(7~40) × L | |||

(10~30) ×(20~40) × L | |||