- Home

- >

- Products

- >

- Tungsten Carbide CNC Inserts

- >

- Tungsten Carbide CNC Turning Tool Inserts

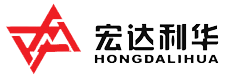

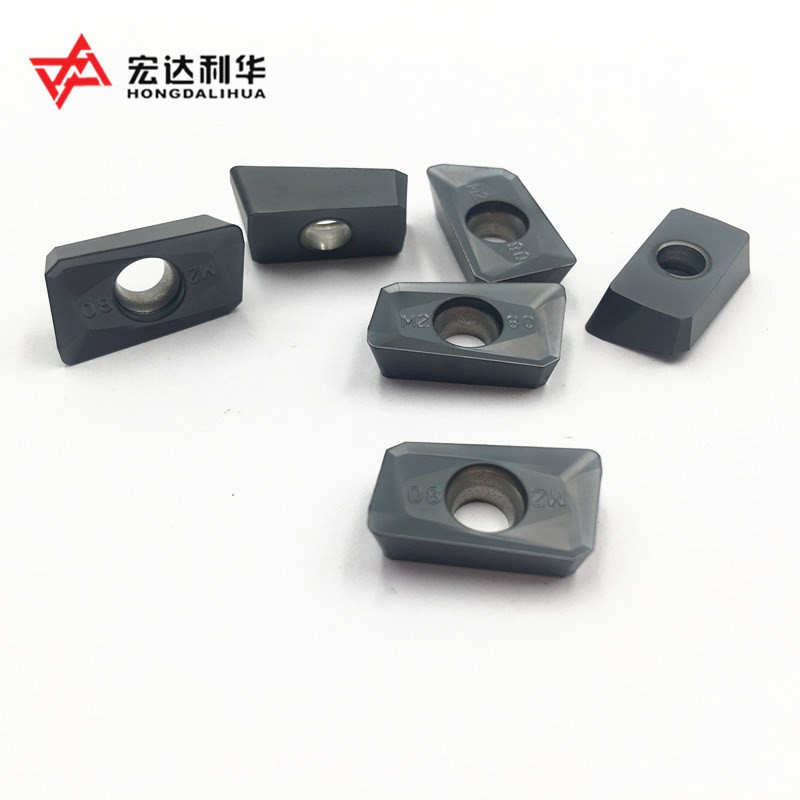

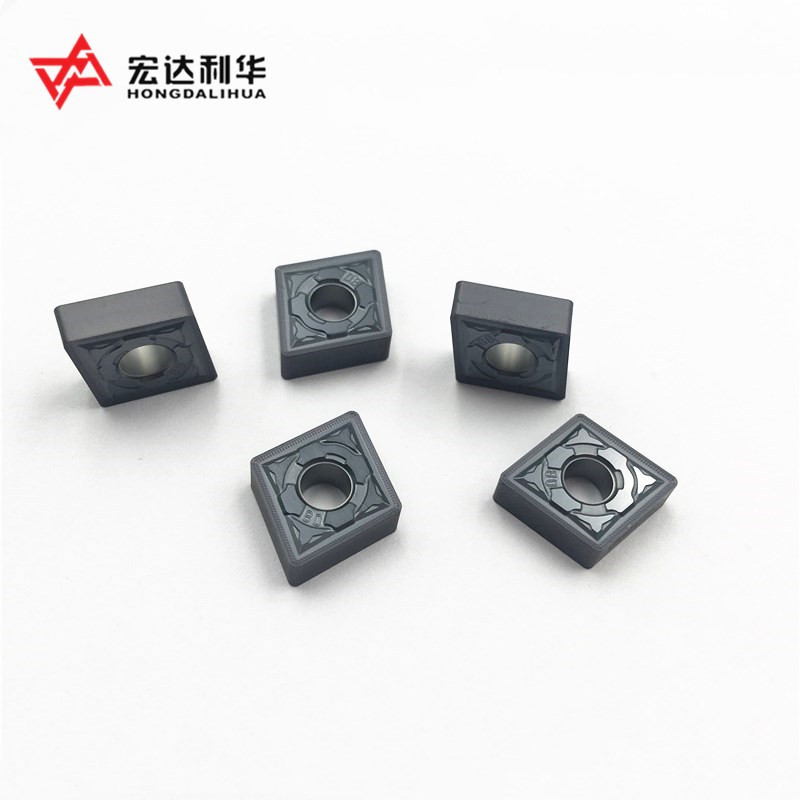

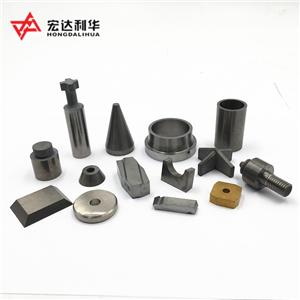

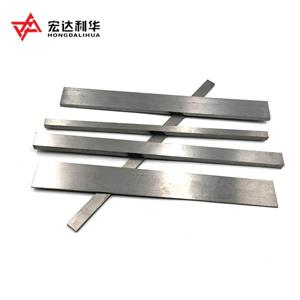

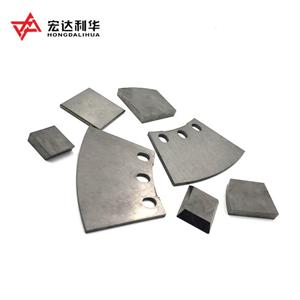

Tungsten Carbide CNC Turning Tool Inserts

Brand :LIHUA

Product origin :Zhuzhou ,China

Delivery time :7-15 working days

Supply capacity :15 Ton per Month

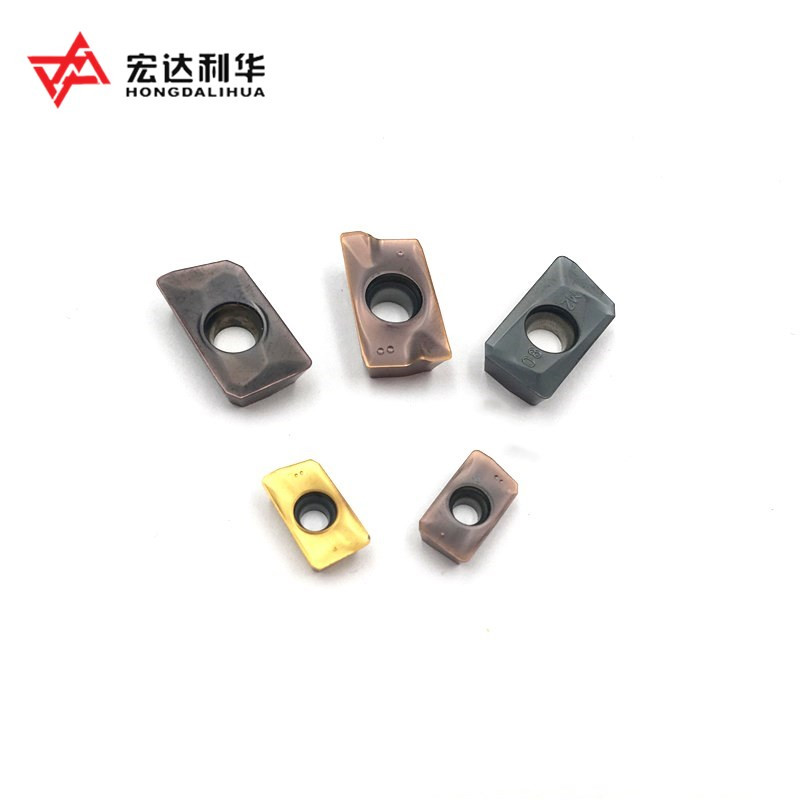

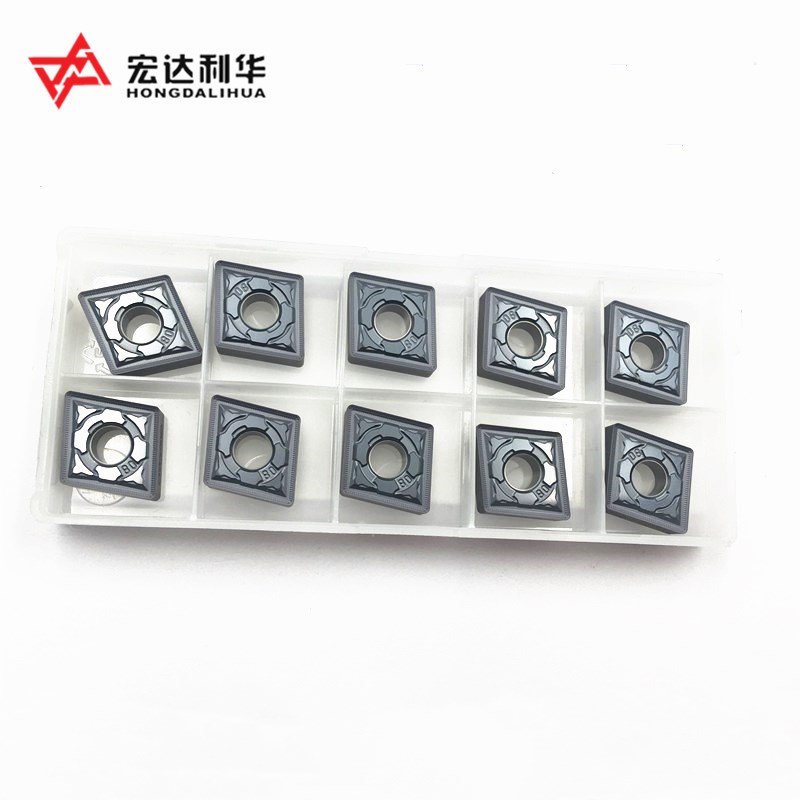

Buy Supply Tungsten Carbide grooving CNC Turning Tool Inserts price Tungsten Carbide blade is used for cutting wood, metal, or other hard materials. Can be hand-operated or power-driven.

Buy Tungsten Carbide CNC Turning Tool Inserts, Supply tungsten carbide tool inserts, Carbide grooving tool inserts price

Applications

Tungsten Carbide blade is used for cutting wood, metal, or other hard materials.

Can be hand-operated or power-driven.

Our carbide inserts have used in surface processing of cast irons, colored metal and alloys, as well as nonmetal materials for hard metal, carbide rough turn, rough planning, and precision milling.

Applicable Machine | Tungsten carbide inserts for turning, milling, threading, grooving tool, cutting tools, etc. |

Stock | For standard, have enough in stock |

For non-standard, need to be customized | |

Nonstandard order | Customize as request |

Packing: | Can laser printing your logo and packing with your label |

Coating: | CVD or PVD coating or as your require |

Suitable for steel , cast iron , stainless steel etc materials | |

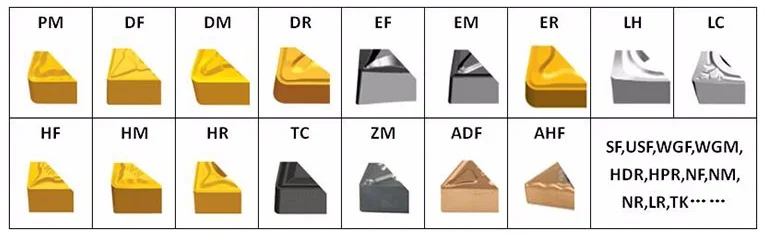

Product Model

No | Chip Breaker | Introduction |

1 | PM | Double sided chip breaker for medium machining. Wide range of application in steel and cast iron. |

2 | DF | Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. |

3 | DM | Double sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. |

4 | DR | Double sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. |

5 | EF | Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. |

6 | EM | Double sided chip breaker with sharp cutting edge and large rake angle. Process reliable medium machining of stainless steel. |

7 | ER | Double sided chip breaker with large rake angle for low cutting forces. Suitable for roughing of stainless steel. |

8 | LH | Single sided chipbreaker for machining of cast aluminium alloys. Sharp cutting edge with positive rake angle. G-tolerance for high repeatability. |

9 | LC | Single sided chip breaker with excellent cutting edge design. Sharp cutting edge with positive rake angle. G-tolerance for |

10 | HF | Single sided chip breaker with good chip control. Suitable for finishing to medium machining of steel and cast iron. |

11 | HM | Single sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. |

12 | HR | Single sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. |

13 | TC | Double sided chip breaker with surrounding cutting edge. Process reliable machining due to highest cutting edge stability. |

MORE DETAILS,PLS CONTACT US . | ||

Tungsten Carbide CNC Inserts Grade Information

| Grade Recommendation of Tungsten Carbide Inserts | |

Grade | Applications |

YBC151 | High wear resistance of the matrix and MT-TiCN, thick Al2O3 and TiN coating. |

YBC152 | Thick TiCN and Al2O3 coating |

YBC251 | tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating. |

YBC252 | Tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating. |

YBC351 | Tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating. |

YBG102 | nc-TiAN coating and fine-grained matrix. |

YBG202 | nc-TiAN coating and fine-grained matrix. |

YBG205 | Added abrasion resistance and high temperature rare elements ultrafine TiAlN based nano-coating. High layer hardness and excellent resistance to high temperature provide effective protection for the cutting edge. |

YBG302 | nc-TiAN coating and flexible cemented carbide matrix. |

YBM151 | Special organizational structure and TiCN, thin Al2O3 and TiN coating. |

YBM251 | Good toughness and strength matrix and TiCN, thin Al2O3 and TiN coating. |

YBM253 | With the advance extra fine grain nanometer coating technology, match up with the high toughness gradient matrix. |

YBD052 | CVD coating(extra thick Al2O3 & thick TiCN), hard matrix. |

YBD102 | CVD coating (thick Al2O3 & thick TiCN) , hard matrix. |

YBD152 | CVD coating (thick Al2O3 & thick TiCN), hard matrix, it is anti-stripping. |

YBD252 | CVD coating (middle thick Al2O3 & thick TiCN), hard matrix. |

YNG151 | Uniform particle refining organizational ceramal alloy, homogenizing organizational & ring form phase structure, Strengthen bond phase,grain boundary composition design. |

YNG151C | Physics weather deposit (PVD) coating, high toughness ceramal matrix. |

YD101 | Fine particle hardness phase WC and bond phase Co. |

YD201 | Middle particle hardness phase WC and bond phase Co. |

High Wear Resistance Tungsten Carbide Nozzle For 3D Printer

Well resistance Tungsten 3D Printer nozzles with 0.4mm filament & M6 thread

High Purity Tungsten Carbide HRA89 3D Printer Extruder Nozzles With Different Orifice