- Home

- >

- Products

- >

- Tungsten Carbide Tool Holder

- >

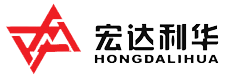

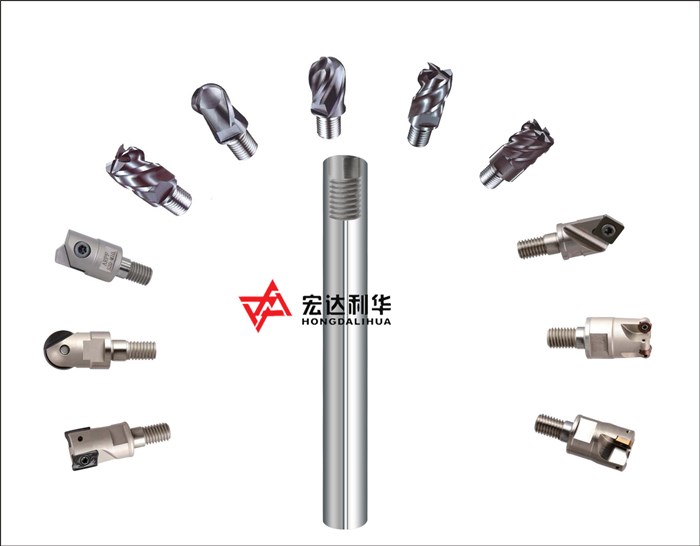

- Tungsten Carbide Extensions ,Milling shanks with high vibrations

Tungsten Carbide Extensions ,Milling shanks with high vibrations

Brand :Lihua

Product origin :Zhuzhou, China

Delivery time :7-15 Working Days

Supply capacity :5000 Piece per Month

1.High Rigidity

Improve surface finish and perpendicularity. Made of pure tungsten carbide material, excellent rigidity, good shock absorption, no distortion as lateral stiffness too large.

2.High Precision

Improve dimensional precision. To extend the processing depth, enhance the accuracy of processing & to achieve long, ultra-deep, ultra-high precision machining possibilities.

3. High Efficiency

No welding fracture concerns, emphasizing the variability of the replaceable tool head, a carbide bar can reach dozens of combinations, widely used in Rough & precision processing industrial .

4. Reduce Cost

Extending the tool life. The Holder can be reused even if the cutter is damaged and Easy and convenient to replace. The tip and the Holder are screwed and run in reverse direction to the spindle.

Tungsten Carbide Extensions ,Milling shanks with high vibrations

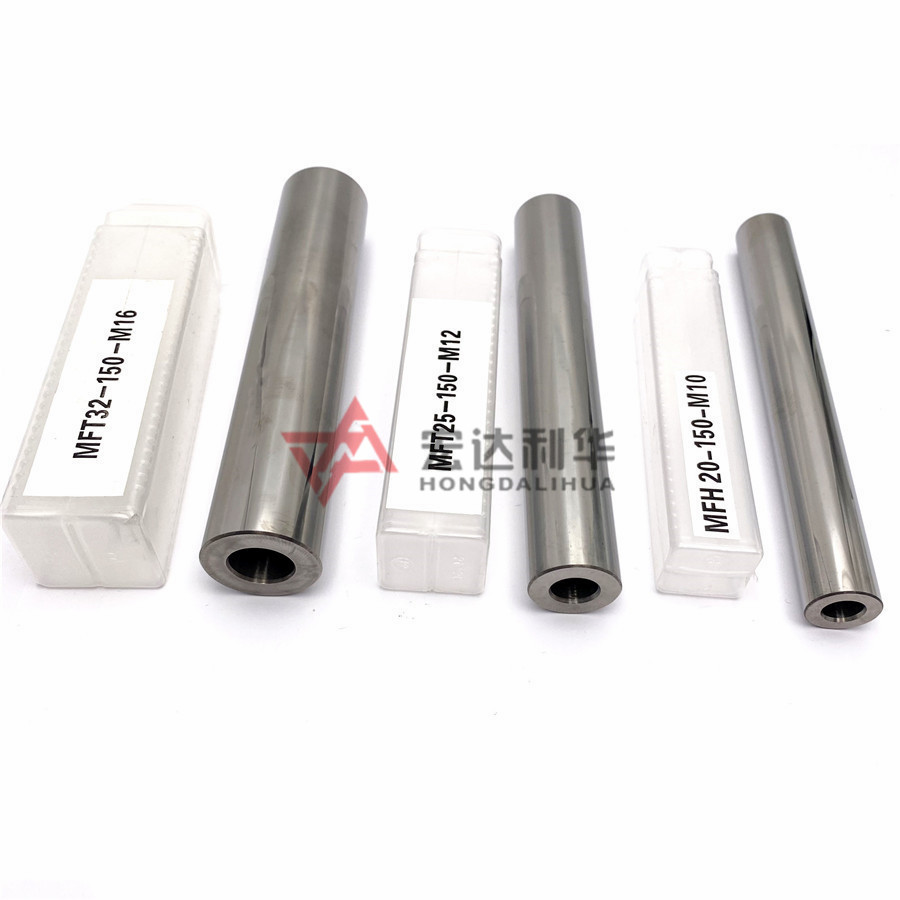

Customized CNC Lathe Tools/Milling Cutter Tungsten Carbide Rod Boring Round Bar

It is an important tool for for machining in CNC machining, Its purpose to prevent tools from shanking and to control, make tools vibarte which also called CNC extension rod.

Especially as the CNC precision machining developing, the traditional CNC machining from 5000 rpm, 6000 to 8000 rpm,after more sophisticated and efficient cutting speed will be developed to more than 20,000 turn.

Such high-speed cutting, Higher requirements of sufficient seismic performances is needed carbide stamping pole must be uniform material, consistent performance of its and Precision concentric assurance to achieve such a high speed cutting operation requirements.

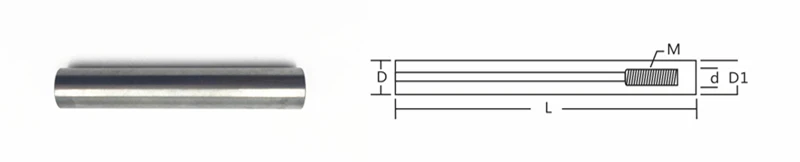

Carbide Screwed Boring Bar

Specification | D(mm) | L(mm) | D1(mm) | M |

MFT-08-100-M4 | 8 | 100 | 8 | M4 |

MFT-10-80-M5/M6 | 10 | 80 | 10 | M5/M6 |

MFT-10-100-M5/M6 | 10 | 100 | 10 | M5/M6 |

MFT-10-150-M5/M6 | 10 | 150 | 10 | M5/M6 |

MFT-12-100-M6 | 12 | 100 | 12 | M6 |

MFT-12-150-M6 | 12 | 150 | 12 | M6 |

MFT-15-100-M8 | 15 | 100 | 15 | M8 |

MFT-15-150-M8 | 15 | 150 | 15 | M8 |

MFT-15-200-M8 | 15 | 200 | 15 | M8 |

MFT-15.6-150-M8 | 15.6 | 150 | 15.6 | M8 |

MFT-15.6-200-M8 | 15.6 | 200 | 15.6 | M8 |

MFT-15.6-250-M8 | 15.6 | 250 | 15.6 | M8 |

MFT-16-100-M8 | 16 | 100 | 16 | M8 |

MFT-16-150-M8 | 16 | 150 | 16 | M8 |

MFT-16-200-M8 | 16 | 200 | 16 | M8 |

MFT-16-250-M8 | 16 | 250 | 16 | M8 |

MFT-16-300-M8 | 16 | 300 | 16 | M8 |

MFT-19-150-M10 | 19 | 150 | 19 | M10 |

MFT-19-200-M10 | 19 | 200 | 19 | M10 |

MFT- 19-250-M10 | 19 | 250 | 19 | M10 |

MFT-20-100-M10 | 20 | 100 | 20 | M10 |

MFT-20-150-M10 | 20 | 150 | 20 | M10 |

MFT-20-200-M10 | 20 | 200 | 20 | M10 |

MFT-20-250-M10 | 20 | 250 | 20 | M10 |

MFT- 20-300-M10 | 20 | 300 | 20 | M10 |

MFT-24-150-M12 | 24 | 150 | 24 | M12 |

MFT-24-200-M12 | 24 | 200 | 24 | M12 |

MFT-24-250-M12 | 24 | 250 | 24 | M12 |

MFT-24-300-M12 | 24 | 300 | 24 | M12 |

MFT-25-150-M12 | 25 | 150 | 25 | M12 |

MFT-25-200-M12 | 25 | 200 | 25 | M12 |

MFT-25-250-M12 | 25 | 250 | 25 | M12 |

MFT-25-300-M12 | 25 | 300 | 25 | M12 |

MFT-32-150-M16 | 32 | 150 | 32 | M16 |

MFT-32-200-M16 | 32 | 200 | 32 | M16 |

MFT-32-250-M16 | 32 | 250 | 32 | M16 |

MFT-32-300-M16 | 32 | 300 | 32 | M16 |

MFT-32-350-M16 | 32 | 350 | 32 | M16 |

MFT-32-400-M16 | 32 | 400 | 32 | M16 |

Customized Carbide Screwed Boring Bar

Specification | D (mm) | D1 (mm) | L | L1 | M |

MFT10-50-150-M6 | 10 | 9.5 | 150 | 50 | M6 |

MFT12-50-150-M6 | 12 | 11.5 | 150 | 50 | M6 |

MFT16-50-150-M8 | 16 | 15.5 | 150 | 50 | M8 |

MFT16-50-200-M8 | 16 | 15.5 | 200 | 50 | M8 |

MFT16-70-250-M8 | 16 | 15.5 | 250 | 70 | M8 |

MFT16-85-120-M8 | 16 | 15.6 | 120 | 85 | M8 |

MFT16-95-150-M8 | 16 | 15.6 | 150 | 95 | M8 |

MFT16-145-200-M8 | 16 | 15.6 | 200 | 145 | M8 |

MFT20-40-100-M10 | 20 | 19.6 | 100 | 40 | M10 |

MFT20-90-150-M10 | 20 | 19.6 | 150 | 90 | M10 |

MFT20-140-200-M10 | 20 | 19.6 | 200 | 140 | M10 |

MFT25-40-100-M12 | 25 | 24.6 | 100 | 40 | M12 |

MFT25-85-150-M12 | 25 | 24.6 | 150 | 85 | M12 |

MFT25-135-200-M12 | 25 | 24.6 | 200 | 135 | M12 |

MFT32-70-200-M16 | 32 | 31 | 200 | 70 | M16 |

MFT32-130-300-M16 | 32 | 31 | 300 | 130 | M16 |

MFT32-150-350-M16 | 32 | 31 | 350 | 150 | M16 |

Customized Carbide Screwed Boring Bar

Specification | D (mm) | D1 (mm) | L | L1 | M |

MFT16-85-120-M8 | 16 | 15.6 | 120 | 85 | M8 |

MFT16-95-150-M8 | 16 | 15.6 | 150 | 95 | M8 |

MFT16-145-200-M8 | 16 | 15.6 | 200 | 145 | M8 |

MFT20-40--100-M10 | 20 | 19.6 | 100 | 100 | M10 |

MFT20-90-150-M10 | 20 | 19.6 | 150 | 150 | M10 |

MFT20-140-200-M10 | 20 | 19.6 | 200 | 200 | M10 |

MFT25-40-100-M12 | 25 | 24.6 | 100 | 100 | M12 |

MFT25-85-150-M12 | 25 | 24.6 | 150 | 150 | M12 |

MFT25-135-200-M12 | 25 | 24.6 | 200 | 200 | M12 |