- Home

- >

- News

- >

- Industry News

- >

- The advantages of cemented carbide anti-seismic tool rod

The advantages of cemented carbide anti-seismic tool rod

The advantages of cemented carbide anti-seismic tool rod

Seismic tool rod is an important tool in the numerical control machining parts, the purpose is to to the vibration of the cutting tools have certain effect to prevent, to control the vibration of the tool, or the ability to do your best not to generate a vibration cutting tool, mechanical machining, the vibration of the cutting tool are inevitable, so there is no way to change this fact, you should choose to use a tool rod can play a role in seismic control.

Aseismic cutter rod is also known as CNC extension rod, especially the development of CNC precision machining, the traditional CNC machining from 5,000 to 6,000 to 8,000 turns, the more accurate and efficient cutting speed will develop to more than 20,000 turns. Such high speed cutting, the speed of the tool bar to use the requirements of higher requirements, must have enough seismic performance, and to achieve such high speed cutting work requirements of seismic performance of the cemented carbide tool bar must be uniform material, perfect consistency and precision concentricity guarantee.

Not good to prevent vibration of a tool, will easily be tool damage, if the tool once broken will require new installing a new cutting tool, not only delay the time, also would increase the cost of industry, so in industrial processing, seismic tool rod of choice is very important, some people say that the cost of this kind of tool rod is higher, but think about it from a different Angle, if you don't choose to use this particular tool rod, so the damaged tooling cost will be more high, in fact is a truth, and frequent replacement of the cutting tool will affect the factory processing process, not only delay the schedule, also affect the rate of completion, It has a great influence on the production efficiency of enterprises.

The vibration of the numerical control cutting tools in mechanical machining industry is the biggest enemy and mechanical processing killer, because this kind of mechanical vibration is inevitable, and the mechanical vibration effect on the mechanical artifacts to cause a decline in precision of workpiece greatly, after serious even scrapped, so how to control and solve this kind of mechanical vibration has become an important subject of mechanical processing industry, under the background of this nc tool requires a special seismic carbide tool rod, carbide seismic tool rod made full use of the materials properties of cemented carbide, and in order to facilitate users to save cost use lock teeth type design, Liberated the nc cutter bit operating space, solid carbide carbide seismic tool rod adopted a round rod processing molding, to ensure the integrity of hard alloy material to alloy material deformation of high hardness give full play to the characteristics of low volume amplification, machining stability factor greatly surpass the stability of ordinary steel bar, let the mechanical vibration value is minimum. The length to diameter ratio of cemented carbide anti-seismic tool rod is large. Such design can make the anti-seismic tool rod more suitable for the high-difficulty and high anti-seismic requirements of small-diameter deep hole machining.

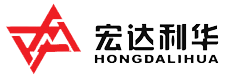

Most of the seismic cutter rod is hollow, which can minimize the vibration generated during processing. This kind of seismic cutter rod is suitable for high-precision machining in the machining center, and can also be used in high-speed precision carving and high-speed milling. The main characteristics are as follows:

1. Made of all-tungsten carbide material, with excellent rigidity, good shock absorption, and no distortion due to excessive transverse force.

2. Extend the machining depth, improve the machining surface accuracy, and realize the possibility of ultra-long, ultra-deep and ultra-high precision machining.

3. There is no concern of welding fracture, emphasizing the variability of the tool head, a cemented carbide tool rod can be up to dozens of combinations, which can cover all processing requirements from rough to fine.

4. The tool head and the tool rod are connected by thread, and operate inversely with the direction of the spindle.

5. Even if the head is damaged, the blade can be reused! And in the machine tool can be convenient and rapid replacement of the tool.

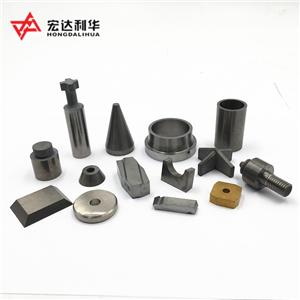

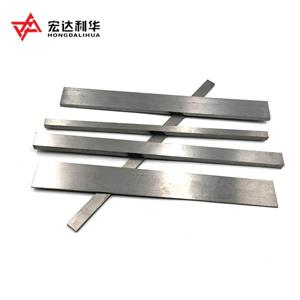

Hard alloy anti-seismic tool rod adopts dry bag type isostatic pressure to produce the alloy tool rod blank, which effectively ensures the uniform and consistent material quality of the whole tool rod. Coarse grinding and fine grinding adopt high-precision processing equipment to ensure the concentricity of the anti-seismic tool rod, which can effectively reduce the eccentric oscillation caused by high-speed cutting. Its basic performance is as follows:

High rigidity: made of high toughness tungsten carbide by pressing and sintering. The toughness strength "4200MPA" and fracture toughness "9.8kic retain the wear resistance of tungsten steel and improve the rigidity of tungsten steel.

High precision: the concentricity, straightness, perpendicularity and roundness of products processed by high-precision CNC internal and external circular grinding machines, centerless grinding machines and internal thread grinding machines are guaranteed to be "0.003mm" and the combined precision is less than or equal to 0.02mm.

High hardness: the WC grain size of 0.8-1.2 PM tungsten carbide powder with high purity, HRA acuity 90.5 °, the cobalt content in 10% 13%, make the tungsten steel seismic tool rod has the high hardness, excellent wear resistance and bending strength.

High seismic resistance: ultra-hard tungsten carbide knife rod, using advanced raw materials and pressing sintering technology, so that the product has a higher seismic performance, seismic diameter ratio is greater than 1:10 diameter.

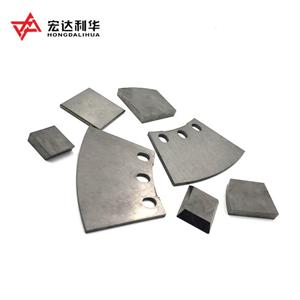

Carbide seismic cutter rod.