- Home

- >

- News

- >

- Industry News

- >

- Characteristics and USES of cemented carbide nozzles

Characteristics and USES of cemented carbide nozzles

Characteristics and USES of cemented carbide nozzles

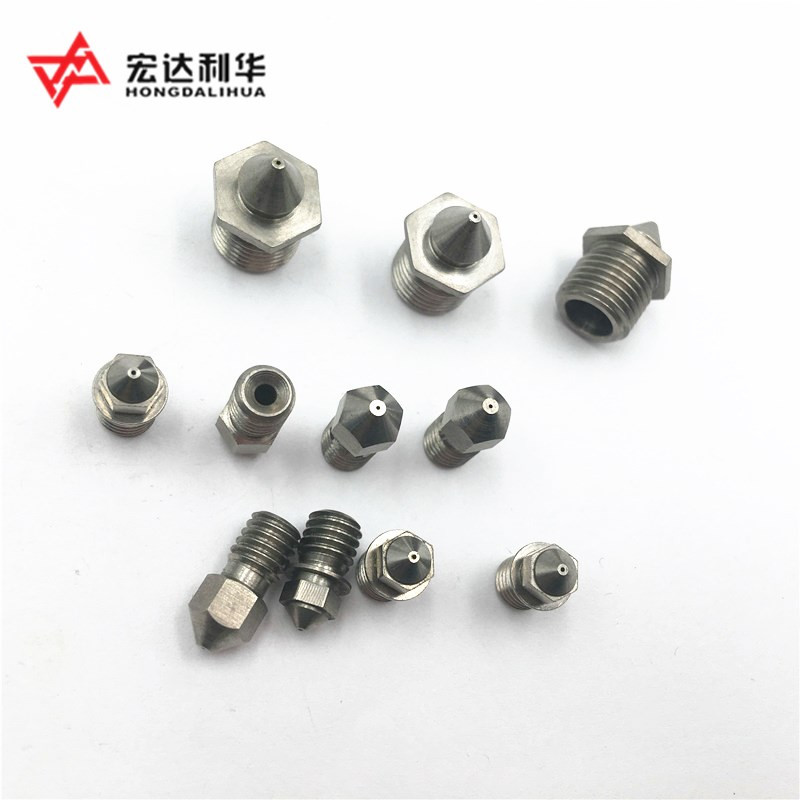

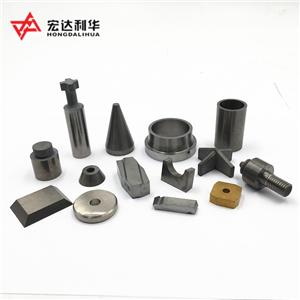

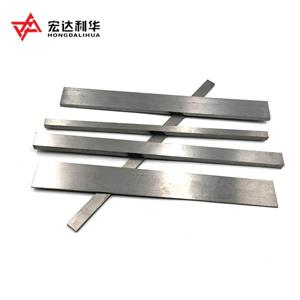

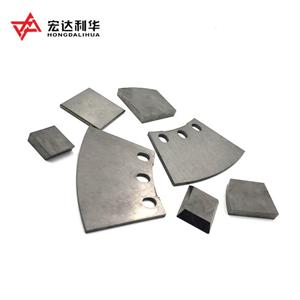

cemented carbide nozzles is machined with precision machinery and cemented carbide material (superhard alloy). The bending resistance reaches 2300N/mm, and the hardness reaches HRA90 degrees. When machining the cemented carbide nozzle, we achieve precision grinding machining and surface treatment, and achieve the roughness of hole Ra0.1 and roughness of hole Ra0.025 at both ends R. There is a scientific radius of curvature design at both entrances. This design ensures the thread passes smoothly. Because of the overall material processing, there is no elevation Angle in the drill hole, and the ease of bending and clogging has been improved relative to the ruby nozzle. Cemented carbide nozzles are formed by hot pressing and sintering of hot straight holes and buttonholes. Due to its hardness, low density and excellent wear resistance and corrosion resistance, cemented carbide nozzles have been widely used in sandblasting and shot-peening equipment, ensuring that the products in the best air and abrasive for a long time to use.

A cemented carbide nozzle is a device designed to control the direction of an object as it enters (or exits) a closed chamber or tube or an opening for special gas flow (especially to increase speed). On the nozzle side, cemented carbide nozzles are the strongest and most cost-effective.

Advantages of cemented carbide nozzle: corrosion resistance, long service life, excellent performance, high cost performance, not easy to wear.

Carbide nozzles and other nozzles: commonly used nozzle materials include cast iron, ceramics, tungsten carbide, silicon carbide, boron carbide. Ceramic nozzles are used only in non-aggressive light equipment and explosive cabinets for abrasive. Tungsten, silicon, boron carbide are the most popular widely used explosives due to their long service life. Comparisons between cemented carbide nozzles and the service life of other nozzles are listed below.