- Home

- >

- News

- >

- Industry News

- >

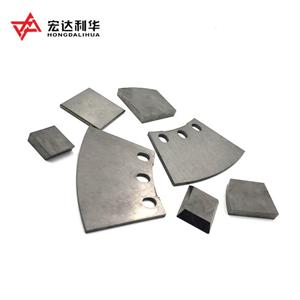

- Advantages and USES of carbide cutting tools(Tungsten Carbide Saw Blades)

Advantages and USES of carbide cutting tools(Tungsten Carbide Saw Blades)

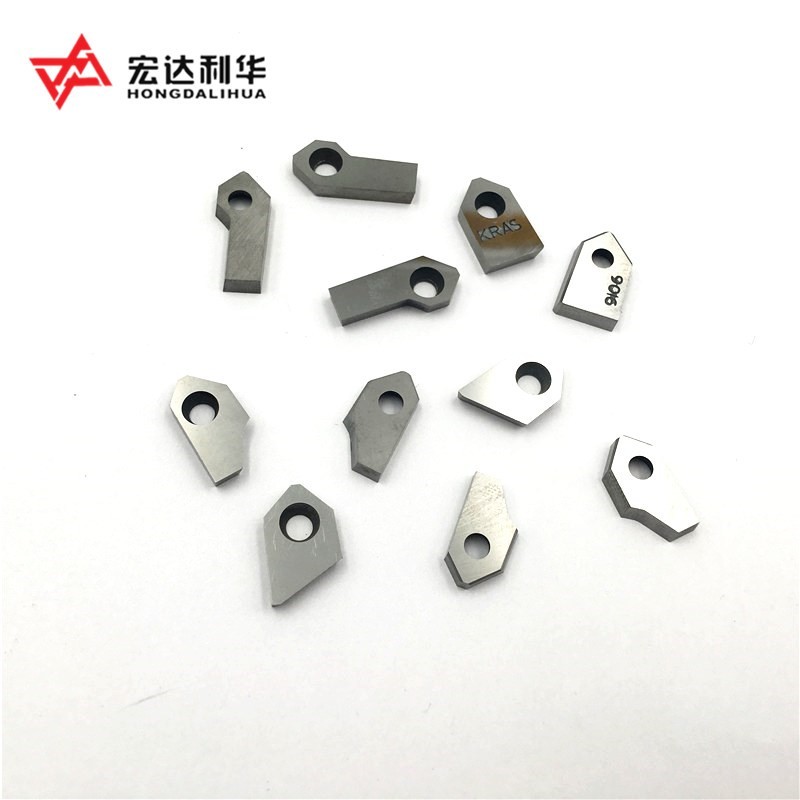

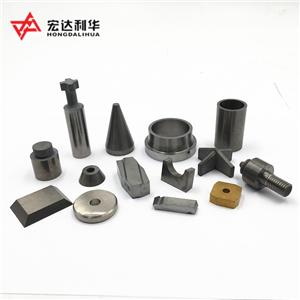

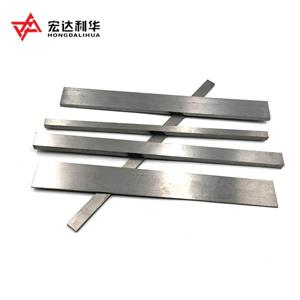

Our circular saw blade has the following advantages:

1, using high-quality tungsten steel, high hardness, low cutting noise, long service life, not easy to wear;

2. Serrated blade, expansion groove design, high cutting precision;

3. Direct supply from the factory, fast delivery and guaranteed delivery time;

4. Complete models, good technical innovation ability, and accept processing with drawings and samples.

Size and specification:

20 ~ 400mm outside diameter, hole diameter 5 ~ 40mm thickness, 0.2 ~ 7.0mm tooth type: no tooth, coarse tooth, middle tooth, fine tooth tooth opening: milling teeth, grinding teeth, not grinding teeth, full grinding tooth tooth shape: sharp teeth, circular arc teeth, staggered teeth (left and right teeth, high and low teeth), R teeth, Angle teeth, tooth surface coating of different teeth: color, all kinds of coating. Material: cemented carbide (tungsten steel K10, K15) forging high performance high speed steel M42,W18Cr4V(W18),6542(M2),W9Mo3Cr4V(W9), etc

Application:

It is mainly used for milling, cutting and sawing of ordinary steel, stainless steel, brass, aluminum alloy, plastic, titanium alloy, superhard cast iron, high nickel white copper, heat resistant alloy, structural steel, alloy steel, cast steel, high manganese steel and other materials.

Special note: receive non - standard custom, special custom. The pictures are for reference only. Can be customized according to customer needs required external diameter, internal hole, thickness, the number of teeth different treatment.

Precautions for the use of carbide circular saw blades

1. The new installation of the saw blade when the trial run in order to ensure that it has a long service life, it's best to let the circular saw machine and new blade replacement or ground again saw blade (re) have a good run-in period, in the first 10 minutes of blade cutting, reduce the feed speed is of great necessity, can return to normal after 10 minutes of feed speed.

2. The speed of feeding and cutting depends on the section and toughness of the material being cut. For materials with high toughness and difficult cutting, the corresponding reduction of feeding is very helpful to improve the service life of the saw blade.

3. If the speed of feeding is increased when cutting the same material, the corresponding saw blade with coarser teeth should be selected.

4. Since the effective cutting Angle and effective tooth pitch are required at any time of cutting materials, regrinding the saw blade in a correct and timely manner is conducive to the maximum effect of the saw blade.

5. By observing the sawdust generated by the saw blade, you can judge whether the current saw blade is cutting briskly and cutting smoothly.